Moinho de bolas para remoção de ferrugem e polimento de superfícies metálicas

Moinho de bolas seco | Máquina de remoção de ferrugem de metal

Diâmetro: 1,2x3m, 1,5x6m, 1,8x6m.

Comprimento: 5,5m, 8m, 9m.

Capacidade de saída: 2-6t/h

Potência do motor: 15kw, 30kw, 45kw

Aplicação: Peças de trabalho metálicas, metal de descarte ou sucata, componentes não metálicos, etc.

Serviço: soluções personalizadas, orientação na instalação e suporte pós-venda.

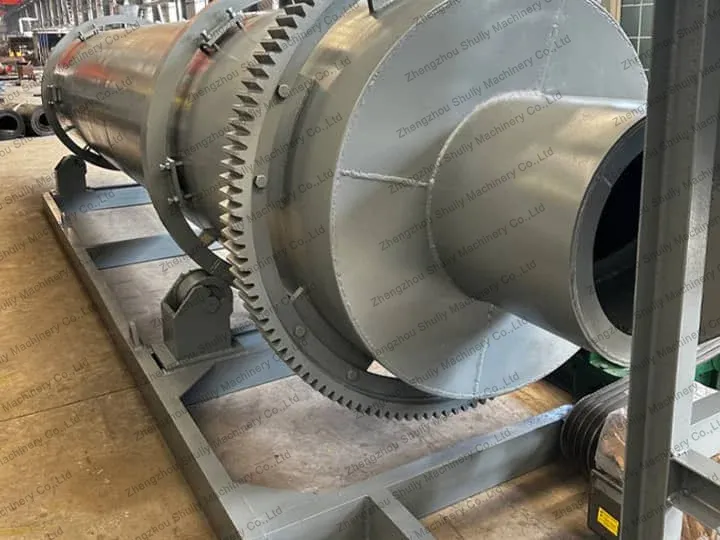

Um moinho de bolas industrial é uma máquina de moagem e polimento de tambor projetada para acabamento eficiente de superfícies de componentes metálicos e não metálicos. É amplamente utilizado para desburring, remoção de ferrugem, arredondamento de bordas e polimento brilhante, especialmente para peças que são facilmente deformáveis.

As moinhos de bolas da Shuli Machinery apresentam uma estrutura mecânica robusta, operação estável e alta eficiência de moagem, tornando-os uma solução ideal para processamento de peças de tamanho médio a grande em indústrias como reciclagem de metal, usinagem e tratamento de superfície.

O que é uma máquina de moagem de moinho de bolas?

Moinhos de bolas secos são usados principalmente para polimento e remoção de ferrugem de materiais de sucata de metal e alumínio com diâmetro inferior a 400 mm. O motor elétrico aciona um redutor, fazendo o tambor cilíndrico girar, enquanto o material e o minério são alimentados no tambor por uma correia transportadora.

O princípio de funcionamento de um moinho de bolas é girar um tambor cilíndrico cheio de meios de moagem (como areia mineral ou bolas de aço). À medida que o tambor gira, os materiais dentro são continuamente tombados, arremessados, esfregados e misturados, removendo efetivamente óleo de superfície, ferrugem e rebarbas.

As peças trabalhadas não só mantêm a sua forma original e precisão dimensional, como também alcançam uma superfície mais lisa, brilhante e limpa. A rugosidade da superfície do produto final melhora-se em 1-2 graus. Portanto, os moinhos de bolas são particularmente adequados para acabamento de superfícies de peças facilmente deformáveis.

Principais vantagens do moinho de bolas Shuliy

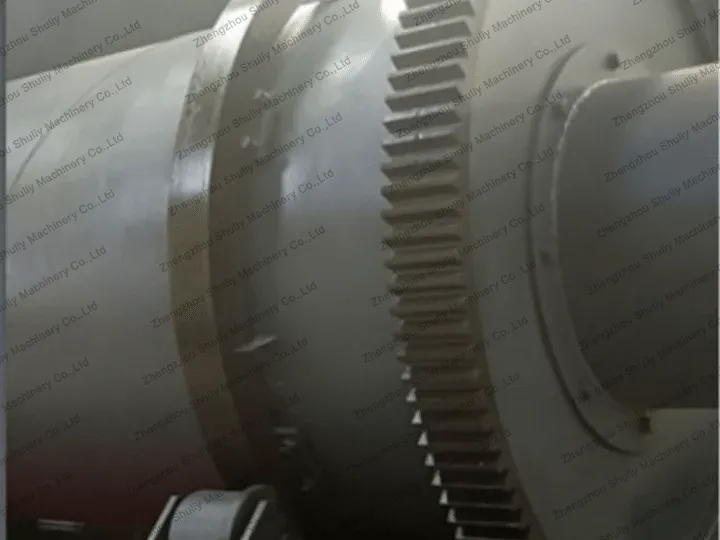

- A engrenagem de abertura dos moinhos de moagem de minério de ferro utiliza um sistema de transmissão de engrenagem de alta resistência e uma estrutura de fundição integrada, resultando em maior estabilidade geral, transmissão mais precisa, maior durabilidade e operação mais suave.

- Nossos moinhos de moagem a seco são fabricados com placas de aço extra espessas, usando soldagem de alta tecnologia e tratamentos de polimento de superfície, proporcionando excelente resistência ao desgaste e impacto, e são projetados para operação industrial pesada.

- Por meio de melhorias, aumentamos a capacidade do alimentador para evitar descarga irregular e sobrecarga, melhorando significativamente a eficiência geral de moagem e garantindo alimentação uniforme do material e resultados de processamento consistentes.

- Além de padrões rigorosos de fabricação, fornecemos um sistema de manutenção abrangente e procedimentos operacionais claros após a compra da máquina, garantindo uma entrega e operação sem preocupações, e conquistando a satisfação e reconhecimento dos clientes.

Aplicações da máquina de remoção de ferrugem de metal

Os moinhos de bolas são amplamente utilizados em várias indústrias e podem processar uma vasta gama de materiais, incluindo:

- Peças e componentes metálicos, ferro sinterizado e metais tratados termicamente, sucata de metal triturada, sucata de alumínio oleosa ou enferrujada, etc.

- Eles também podem processar metais não ferrosos (cobre, ligas de alumínio, etc.) e peças não metálicas que requerem polimento de superfície.

Suas excelentes características o tornam particularmente adequado para peças de tamanho médio a grande que requerem tratamento de superfície de alta qualidade.

A maioria dos nossos clientes utiliza-o para pré-tratamento de reciclagem de metal, moagem e polimento após a fabricação de hardware e fixadores, pré-tratamento de superfície antes de revestimento ou eletrodeposição, e mais.

Tipo de moinho de bolas industrial

Para atender às diversas necessidades de processamento, a Shuli oferece uma variedade de modelos de moinhos de bolas com diferentes diâmetros, comprimentos e capacidades de produção.

| Diâmetro | Comprimento | Saída | Potência do motor |

| 1,2x3m | 5,5m | 2t/h | 15kw |

| 1,5x6m | 8m | 4t/h | 30kw |

| 1,8x6m | 9m | 6t/h | 45kw |

Desde modelos adequados para oficinas pequenas e médias com capacidade de produção de 2 toneladas por hora, até modelos para produção industrial em grande escala com capacidade de 6 toneladas por hora, os clientes podem escolher o modelo mais adequado com base no tipo de material, carga de trabalho e espaço na fábrica.

Se não tiver certeza de qual modelo é adequado para sua aplicação, nossos engenheiros podem recomendar ou personalizar uma solução com base no seu tamanho de material, grau de corrosão e efeito de tratamento de superfície desejado. Contacte-nos se tiver alguma dúvida sobre este moinho de bolas!

Por que escolher o moinho de bolas Shuliy?

- A Shuliy é uma fabricante profissional com 40 anos de experiência na indústria e mais de uma década de experiência em comércio internacional.

- Nossas máquinas são projetadas de forma flexível e podem ser personalizadas para atender diferentes necessidades.

- Oferecemos preços de fábrica altamente competitivos, preços transparentes, serviço pós-venda abrangente e suporte técnico completo durante todo o processo.

- Temos uma excelente reputação global e um sistema de exportação e envio bem estabelecido, conquistando a confiança de clientes em todo o mundo.

- A Shuliy compromete-se a fornecer soluções de moagem práticas, duráveis e econômicas para o seu negócio, com serviço profissional.

Se procura soluções confiáveis de reciclagem de metal de grau industrial, contacte imediatamente a Shuli Company para especificações técnicas detalhadas, soluções personalizadas de moinho de bolas e uma lista de preços completa.

Clique para ver outros produtos mais vendidos: Triturador de tambor de aço, Tesoura de corte de metal.