Shuliy Helped Saudi Arabia Install Gantry Shear

A Saudi Arabian recycling company specializing in large-scale scrap metal processing planned to introduce a high-efficiency gantry shear to increase its processing capacity. Due to the gantry shear’s large size and complex installation, Shuliy engineers went to the site to assist with the installation.

Why was a gantry shear chosen for this project?

Before the project began, we conducted several in-depth discussions to understand the client’s needs. Their raw materials consisted of tons of strip-shaped scrap metal and reinforcing steel. Direct shredding would not only be inefficient but also prone to safety accidents.

Furthermore, due to the irregular shape and heavy weight of the materials, they were difficult to process with small or manual shearing equipment. A gantry shear became the best choice, perfectly meeting the client’s requirements for safety, cutting efficiency, and system stability.

Shuliy solution: Gantry shear + On-site installation

After fully understanding the client’s material type, processing capacity requirements, and site conditions, Shuliy recommended a heavy-duty gantry shear suitable for scrap metal recycling plants.

To ensure the smooth progress of the project, Shuliy dispatched an experienced engineering team to Saudi Arabia to be responsible for on-site equipment installation, system commissioning and testing, as well as providing operator guidance and basic training.

On-site Installation & Commissioning

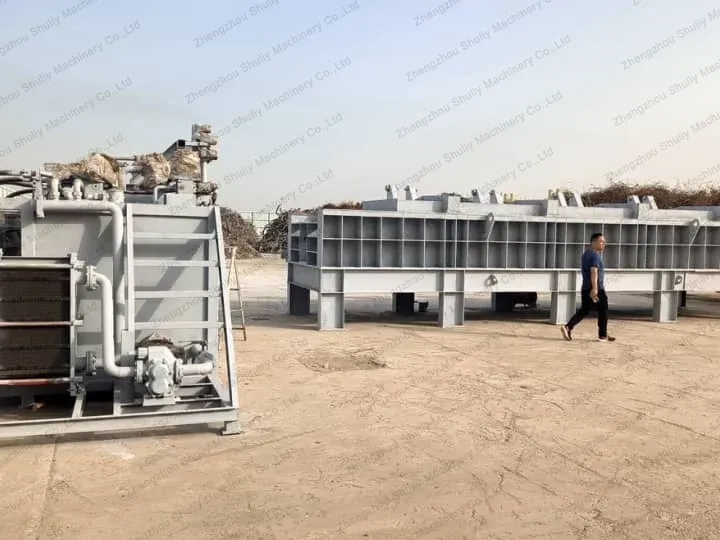

During the installation process, the Shuily engineering team worked closely with the client’s local operators. The gantry shear was installed directly next to the waste pile at the recycling center.

After installation, the machine was tested using actual scrap metal to determine the following:

- Whether the cutting performance could achieve the expected efficiency and output

- Whether the hydraulic system and safety devices could operate stably

Finally, upon the successful completion of the project, the client expressed sincere praise to Shuily.

“It’s wonderful to work with your company. I never expected this project to be completed so smoothly within budget. Thank you for your technical support.”

Project conclusion

After successful commissioning, the gantry shear helped the customer:

- Significantly improve scrap metal processing efficiency

- Reduce manual labor intensity and operational risks

- Achieve more standardized and controllable scrap cutting

- Lay a solid foundation for the future expansion of recycling capacity

The project was completed, and both teams took a group photo on site to celebrate the successful installation.

If you’re also struggling to implement a recycling project, consider contacting Shuliy for help with everything from their suggestions to installation.