Industial metal baler for scrap metal briquette

Metal Scrap Baler | Metal Compactor

Hot selling models: 125T, 160T, 180T

Capacity: 1200-14000kg/h

Applicable scrap: Steel, iron, copper, aluminum, waste drums, metal shells, etc

Advantages: Various machine models, customization, high-quality machine performance

Service: After-sales service, video guidance, 24/7 online service

Warranty period: 1 year

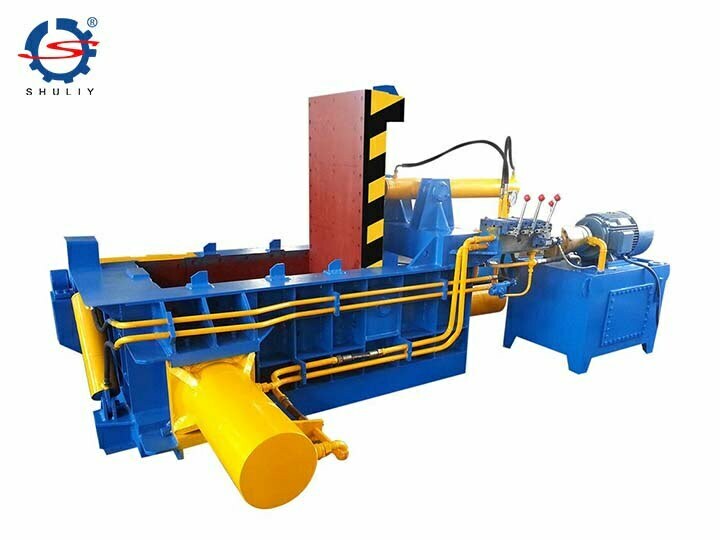

Metal baler is also called scrap metal briquette machine, horizontal metal baler, hydraulic metal baler, and so on. Its main purpose is to press the metal scraps into a specific shape to reduce the volume, to facilitate storage, transportation, and recycling.

Parameters of metal scrap baler for sale

| Type | Nominal push power(Kn) | Compression chamber size (Length * width * height)(mm) | Bale size(mm) | The density of metal blocks(kg/m³) | Capacity(kg/h) | Single-cycle time(s) | Matching power(kW) |

| Y81-1250A | 1250 | 1200*700*600 | 300*300 | ≥2000 | 1200-1800 | ≤120 | 15 |

| Y81-1250B | 1250 | 1400*800*700 | 300*300 | ≥2000 | 1600-2300 | ≤140 | 15 |

| Y81-1350 | 1350 | 1400*600*600 | 600*240 | ≥2000 | 1600-2500 | ≤100 | 18.5 |

| Y81-1600A | 1600 | 1600*1000*800 | 400*400 | ≥2000 | 2000-3500 | ≤120 | 22 |

| Y81-1600B | 1600 | 1600*1200*800 | 400*400 | ≥2000 | 2000-4000 | ≤130 | 30 |

| Y81-2000A | 2000 | 1600*1200*800 | 400*400 | ≥2000 | 2500-4500 | ≤130 | 22/15 |

| Y81-2000B | 2000 | 1800*1400*900 | 450*450 | ≥2000 | 3000-5000 | ≤130 | 30/37 |

| Y81-2500A | 2500 | 2000*1400*900 | 500*500 | ≥2000 | 4000-6300 | ≤130 | 44/60 |

| Y81-2500B | 2500 | 2000*1750*1000 | 500*500 | ≥2000 | 5000-6300 | ≤150 | 44 |

| Y81-2500C | 2500 | 2000*1750*1200 | 600*600 | ≥2000 | 5500-6500 | ≤150 | 60 |

| Y81-2500D | 2500 | 2500*2000*1200 | 600*600 | ≥2000 | 5500-6500 | ≤150 | 60 |

| Y81-3150A | 3150 | 2000*1750*1000 | 500*500 | ≥2000 | 4000-6500 | ≤150 | 60 |

| Y81-3150B | 3150 | 2000*1750*1200 | 600*600 | ≥2000 | 5000-7000 | ≤150 | 60 |

| Y81-3150C | 3150 | 2500*2000*1200 | 600*600 | ≥2000 | 6000-8000 | ≤150 | 90 |

| Y81-3150D | 3150 | 3000*2500*1200 | 600*600 | ≥2000 | 6000-8000 | ≤160 | 90 |

| Y81-4000A | 4000 | 2500*2000*1200 | 600*600 | ≥2000 | 5000-7500 | ≤160 | 90 |

| Y81-4000B | 4000 | 3000*2500*1200 | 600*600 | ≥2000 | 8500-13000 | ≤160 | 90 |

| Y81-4000C | 4000 | 3500*3000*1200 | 600*600 | ≥2000 | 9500-14000 | ≤160 | 90 |

Application of horizontal metal baler

Metal baler machine is suitable for pressing all kinds of scrap metal such as scrap steel, scrap iron, copper, aluminum scrap, aluminum chips, iron sheets, steel shaving, aluminum shaving, waste oil barrel, paint drums and other metal drums and cans, waste automobile shell, waste oil drums, cans, food cans, disintegrated car shell, including body, door, engine block, brake drums, engine parts, suspension parts, various metal wastes, cutting chips, grinding chips, etc. generated during industrial production, etc.

It can be used to make various shapes of blocks (the size of the blocks can be customized) such as the long cube, cylinder, cube, etc., which is convenient for melting and reusing. In addition, it can also be used for the compression of cartons, plastic bottles, and other items.

Structural composition of horizontal metal scrap baler

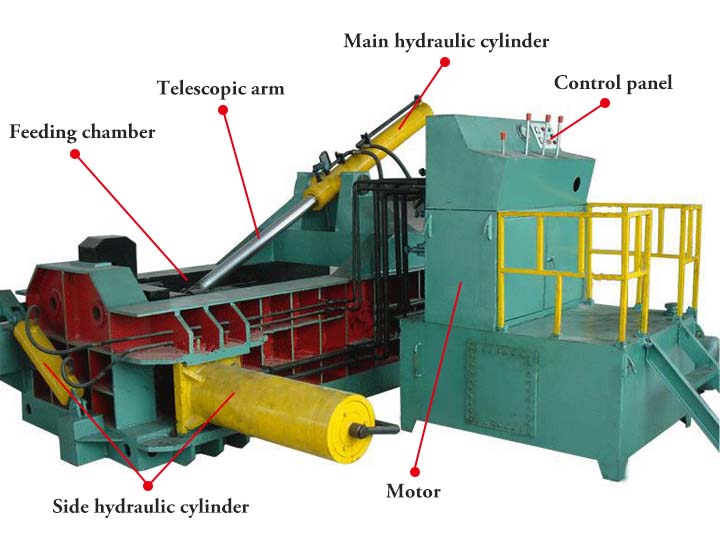

The scrap metal briquette machine is mainly composed of hydraulic parts, a feeding chamber, a door cover, a telescopic arm, a console, a side hydraulic cylinder, a main hydraulic cylinder, a motor, a reducer, a safety device, etc.

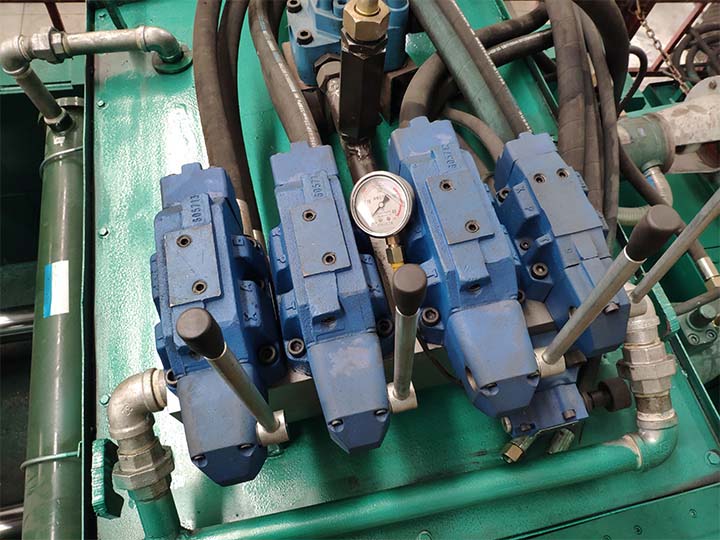

- The hydraulic part is the “heart” of the metal compactor and the power source of the machine. The pressure range of this machine is between 1250kn and 4000kn.

- The feeding chamber determines the size of the materials that can be put in. The size range of the feeding chamber is 1200 * 700 * 600mm – 3500 * 3000 * 1200mm.

- There are four hydraulic cylinders in the machine, one on the door cover, one on the main pusher, one on the side pusher, and one on the outlet part.

- Install an emergency stop device and over-current protection devices to prevent accidents.

How does a metal scrap baler work?

Scrap loading

First, put the material into the feeding chamber of the metal compactor. Note: The materials put in cannot exceed the maximum output of the machine, because the motor will easily damage the motor when it is working under overload.

Start the scrap metal briquette machine

Turn on the power of the machine and operate the operation lever to control the door cover to press down. After the pressing is completed, the door cover and the feed bin form a closed space.

Multi-point hydraulic compression

Hydraulic rods at the back and sides of the metal scrap baler push the material forward and compress continuously, eventually forming a high-density metal block.

Forming and discharging process

The turnover hydraulic rod pushes out the materials in regular shape, and the density can reach 2000 kg / m3. Finally, push out the compacted metal blocks out of baler smoothly. This completes a complete baling operation of the metal scrap.

Advantages of hydraulic scrap metal briquette machine

- The machine is hydraulically driven, with low noise, stable operation, and high safety factors.

- There are a variety of discharge methods, which can be divided into machine discharge and manual discharge. Customers can choose according to their needs.

- In general, the voltage of the machine is 380v, but it can also be adjusted according to customer needs. In the case of inconvenient power sources, diesel engines can be used to provide power.

- The machine is easy to install, no foot screws need to be installed.

- There are various operation modes of the machine, so you can choose manual operation or PLC operation.

- The scrap metal briquette machine parts are precisely processed by a computer numerical control lathe. The machine’s action is soft and durable.

- The machine is made of thickened carbon steel with a beautiful appearance. The machine surface is coated with waterproof and anti-corrosion paint to extend the service life of the machine.

Why choose Shuliy as scrap metal briquette machine supplier?

Shuliy was chosen as a supplier of scrap metal balers because of its competitive advantages in the industry in terms of equipment performance, quality assurance and customer service.

- Reasonable price: Shuliy provides cost-effective scrap metal balers, ensuring that customers can obtain high-quality production equipment while controlling costs.

- Customized service: In response to different customer needs, Schulich can provide personalized customized solutions to design and optimize balers for specific scrap processing scenarios.

- Perfect service: From pre-sales consultation to after-sales installation and maintenance, we provide a one-stop comprehensive service to ensure that customers have no worries.

- Variety of models: We have a variety of specifications of the metal baler series, to meet the needs of different output and material types of baling, to adapt to the trend of market diversification.

How to get more details about metal scrap baler?

For more details or to order Shuliy Horizontal Metal Baler, please visit our official website. At the same time, you can also email, online chat tool for inquiry and communication, we will provide you with professional consulting services about metal recycling timely.