Aluminum can baler machine

| Model | Y81-2000B |

| Nominal push power(Kn) | 2000 |

| Compression chamber size (Length * width * height)(mm) | 1800*1400*900 |

| Bale size(mm) | 450*450 |

| The density of metal blocks(kg/m³) | ≥2000 |

| Capacity(kg/h) | 3000-5000 |

| Single-cycle time (s) | ≤130 |

| Matching power(kW) | 30 or 37 |

You can now ask our project managers for technical details

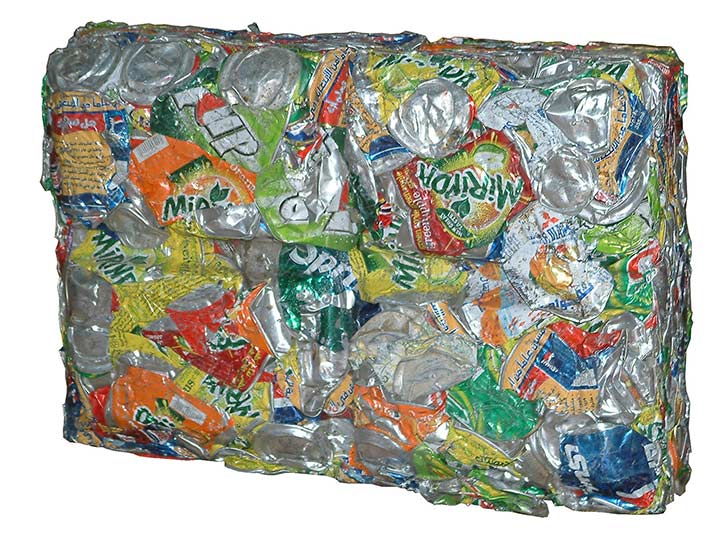

An aluminum can baler machine is a machine suitable for baling and packing various aluminum cans. It is an ideal piece of equipment for recycling various metal cans.

The structure of the aluminum can baler machine

The horizontal metal baler is mainly composed of a hydraulic system, a control system, and a feeding system. The main parts are oil tanks, hydraulic telescopic boom, feeding chamber, side hydraulic rod, pressure plate, control panel, Locking mechanism,

Application prospect of hydraulic metal baler

In the past two years, as people’s sustainable development awareness has been continuously strengthened, more and more people have begun to pay attention to the recycling of resources. As one of the main machines in the metal recycling industry, the aluminum can baler machines can compress light metals into high-density metal blocks, which greatly saves storage and transportation space.

Parameters of the aluminum can baler machine

| Type | Y81-2000B | The density of metal blocks(kg/m³) | ≥2000 |

| Nominal push power(Kn) | 2000 | Capacity(kg/h) | 3000-5000 |

| Compression chamber size (Length * width * height)(mm) | 1800*1400*900 | Single-cycle time (s) | ≤130 |

| Bale size(mm) | 450*450 | Matching power(kW) | 30 or 37 |

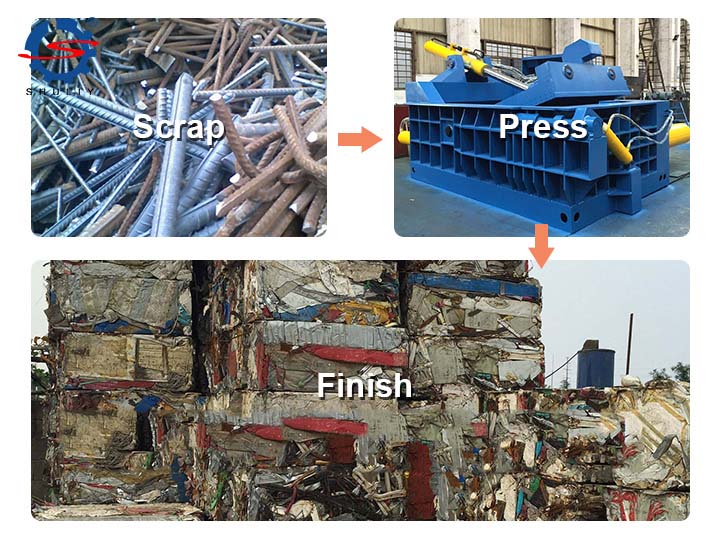

How does an aluminum can baler machine work?

The motion program of the metal briquette machine is as follows:

- The top cover is closed after filling, and it will be locked with a locking mechanism to prevent the top cover from being opened.

- The master cylinder head accelerates forward and slowly advances after reaching the set stroke. Until the waste metal is packed into bales and is equal to the length of the bales, the master cylinder maintains pressure at this time.

- When the main cylinder is holding pressure, the side cylinder fast forwards, and when it reaches a certain position, it switches to slow forward. When the scrap metal is packed into a set-width position, the rear cylinder holds the pressure.

- After the packing is completed, the locking mechanism returns to its original position, and the upper cover is opened.

- The pushing hydraulic shaft pushes the bale out of the machine’s discharge room.

- The front door is closed, immediately enter the next cycle and feed.