Scrap metal cutting shear | alligator steel shear machine

Scrap metal cutting shear also called alligator steel shear machine, is very suitable for cutting long metals. Compared with other cutting equipment, it has the characteristics of a lightweight, small footprint, and high efficiency. Therefore, this machine is often used in rolling mills, metal recycling plants, scrap car dismantling plants, electrical recycling plants, etc. It is very suitable for cutting round steel, angle steel, rebar, wire, iron sheet, color steel tile, aluminum alloy, channel steel, copper plate, iron plate, scrap metal, etc. for subsequent processing.

How does the alligator steel shear machine work?

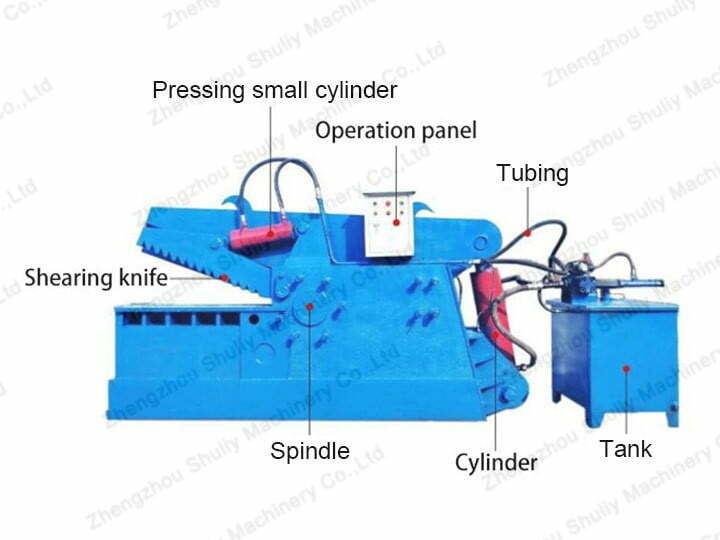

Alligator shears are mainly composed of shearing oil cylinders, shearing knives, pressing knives, pressing oil cylinders, hydraulic pumps, control panels, safety devices, and so on. When the scrap steel cutting shear is working, the hydraulic pump provides power to the pressure knife, and the pressure knife is lowered to hold the material firmly. Then, the hydraulic oil pump fills the cutting cylinder with oil, and the cutter gradually descends to cut the material.

Scrap metal cutting shear application areas

This scrap metal shear can be used in the metal recycling industry, metal processing industry, scrap car processing industry, etc. It can quickly cut some long strips of metal into certain feet of storage. The raw materials that can be processed are metal, iron, steel, color steel tile, aluminum alloy, scrap steel, and iron plate.

Details of scrap metal cutting shear

The pressure will not decrease after years of use, the sealing ring material does not leak oil, and the machine is durable.

Operation panel with automatic functions, square change control, and adjustment

Hydraulic cylinder, no oil leakage, no rust, to ensure smooth metal shear

Shear knife, suitable for various shapes of steel or metal edges

Working principle of scrap metal cutting shear

Crocodile shear structure principle: crocodile shear for the upper and lower crocodile shear structure, through the hydraulic pump drive, to form pressure, in the electromagnetic reversing valve and the control of the oil circuit to achieve the lifting and contraction of the cylinder, through the principle of leverage in the cylinder under the pressure of pushing up the crocodile under pressure auxiliary locking cylinder will be pre-pressure locking material in the main cylinder after the role of continuous pushing up the crocodile knife and the lower crocodile knife to achieve interactive shear will enter, The material entering the cutter is cut off.

Features of the scrap steel cutting shear:

- Low cost. Compared with the gantry shear, the price is much lower. Large metal scraps are rarely found in general metal recycling plants. Conventional scraps can be cut with this machine.

- Small floor area. Due to its small footprint, this machine can be used in many places.

- High working efficiency. This machine can cut 8-12 times in one minute, and the work efficiency is very high.

- Adopting hydraulic transmission mode, has the advantages of stable operation, low noise, and high safety factors.

- Easy installation. This machine does not need to install sole screws, it is simple and flexible to operate, and the cutting surface can be adjusted at will.

Operating instructions for alligator steel shear machine

1. The pressure range of this machine is 100 to 300 tons.

2. The cutter length is 25-120 cm.

3. Both the machine shearing force and the blade length can be customized according to customer needs.

4. Regularly check the oil filter in the fuel tank and remove the foreign matter in time to prevent the oil pipe from being blocked and affecting the working efficiency of the machine.

5. Check whether the screws on the machine are tight and running smoothly every other month.

6. When using the shear, pay attention to the safety of the surrounding personnel. When cutting short materials, use clamps instead of hands.

Auxiliary equipment for scrap metal cutting shear

A conveyor belt can be added to the front of this metal shear, which allows for fully automatic feeding and can also play a role in even feeding. This metal shear conveyor belt is an optional device, you can choose whether to buy it according to the processing conditions need.