Scrap steel shearing machine | car body cutting machine

Scrap steel shearing machine is also called heavy duty gantry shear, hydraulic wase steel cutting machine, car body cutting machine. It is suitable for cutting large and long metal, in order to facilitate secondary processing. The cutting length can be adjusted in strips. It is widely used in scrap car dismantling plants, metal recycling plants, metal smelting and manufacturing industries, and metal trading industries.

The prospect of the waste metal recycling industry

Due to the continuous exploitation and utilization of mineral resources, mine resources have become increasingly scarce. Therefore, the recovery and utilization of waste metal are one of the main ways to save mineral resources. The average recovery level of steel scrap in the world is 48%. Then, there are still 52% unrecycled resources, which is a very serious waste of resources.The metal recycling industry has a broad market prospect, not only can save resources but also has a huge profit and value space. With the development of the economy, many countries’ automobiles, home appliances, mining, and other equipment have nearly entered the retirement period. Take the recycling of end-of-life cars as an example. 82% of the materials in a car are metals, of which 90% can be recycled. The benefits are considerable. The emergence of metal baler machine, briquetting machine, gantry shear, crocodile shear, double-axis shredder and other professional equipment for metal recycling has brought great convenience to the metal recycling industry.

Brief introduction of scrap steel shearing machine

In the process of metal recovery and smelting, the longer metal is not conducive to being put into the furnace for recasting, and the hydraulic scrap iron cutter can quickly cut off these metals. Compared with gas cutting, flame-cutting, and other methods, this method uses cold cutting and does not need additional auxiliary equipment. It is a simple and time-saving and labor-saving method.

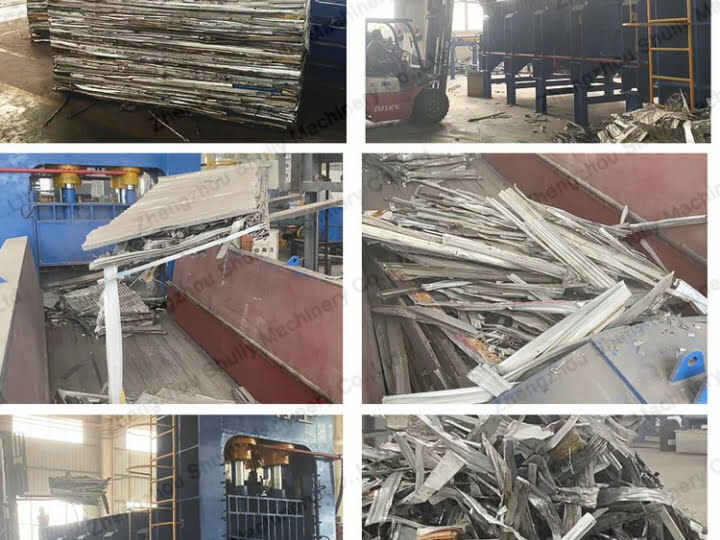

raw materials that can be processed by Scrap steel shearing machine

The metal shearing machine is suitable for iron sheets, steel, steel bars, color steel tiles, aluminum alloys, copper plates, aluminum plates, and iron plates. It is suitable for metal recycling and processing industries, smelting, and automobile dismantling factories. After being cut by the metal shearing machine, the material can be uniform in length, which is convenient for transportation and smelting. And the metal size of the cut metal can be adjusted. Shear force 100 tons to 250 tons. Mainly cut material size (12~20mm)*250mm. The number of cuts is 8 to 12 times per minute.

Raw materials that can be processed by scrap steel shearing machine

The scrap steel shearing machine is suitable for iron sheets, steel, steel bars, color steel tiles, aluminum alloys, copper plates, aluminum plates, and iron plates. It is suitable for metal recycling and processing industries, smelting, and automobile dismantling factories. After being cut by the metal shearing machine, the material can be uniform in length, which is convenient for transportation and smelting. And the metal size of the cut metal can be adjusted. Shear force 100 tons to 250 tons. Mainly cut material size (12~20mm)*250mm. The number of cuts is 8 to 12 times per minute.

How does the gantry shear work?

Gantry shear is mainly composed of fuselage, feeding system, hydraulic system, electrical control system, etc. The sheer force of the machine is from 50t to 1200t. The fuselage is welded with thickened steel plate and reinforced externally, which can bear strong shear force. When working, the grab or other equipment will put the material into the feeding system, and the material will move forward with the conveyor belt. The hydraulic system starts to work and the cutter falls to cut off the material. The feeding speed of the conveyor can be adjusted infinitely. There are side pressure devices on both sides of the machine to fix the materials and speed up the cutting process.

Features of the car body cutting machine

1. The scrap steel shearing machine adopts hydraulic transmission, which has the characteristics of small noise, stable operation, small inertia, and large shear surface, and it is easy to realize overload protection.

2. The size and length of the cutting block can be adjusted, and the adjustment method is convenient.

3. The electrical part adopts an internationally famous brand, Schneider Electric, to guarantee the service life of the machine.

4. The hydraulic traditional system has low machine noise, and high metal cutting efficiency.

5. Plc fully automatic operating system, high degree of machine automation.