How much does a metal shear cost? | Alligator shear price

Metal shear (alligator shear) is looked like an alligator, and their working principle is similar to that of crocodiles, so they are called alligator shears. It is suitable for truncating long metals for processing and recycling and storage. This machine is a hot sale machine in metal recycling plant and automobile recycling processing plant, which can shorten round steel, angle steel, iron sheet, aluminum sheet, stainless steel railing, channel steel, etc. within a really short time.

How much does a metal scrap cutting shear machine cost?

Everyone must know that the price of the machine is often proportional to the quality of the machine, and the price of the machine made of good materials and processes is slightly higher than that of ordinary machines. As a leader in the metal recycling industry, Shuliy Group has more than 10 years of experience in making alligator shear. It can help you customize metal scrap cutting shear machines of different machine materials, different shear forces and different outputs to ensure fair prices.

If you have this need, please contact our professional sales consultants. We are online 24 hours and are willing to provide you with professional answers.

Features of alligators shear:

In short, alligator shear has the characteristics of smooth operation, easy use, excellent quality, and practical functions.

How to use the alligator shear:

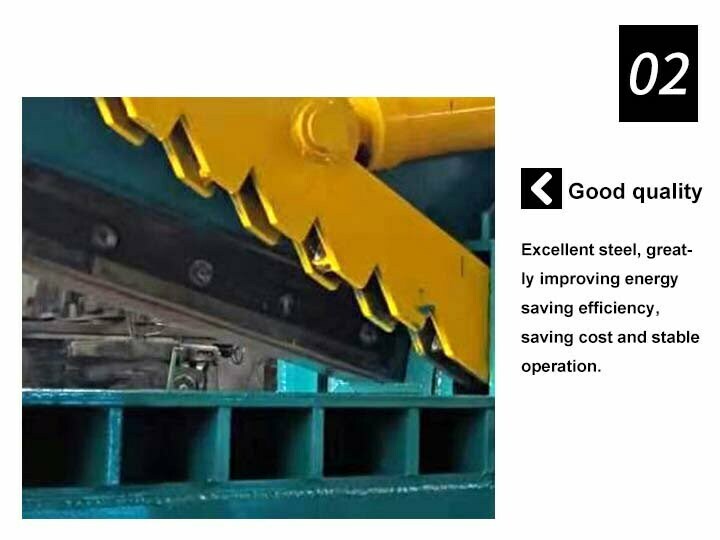

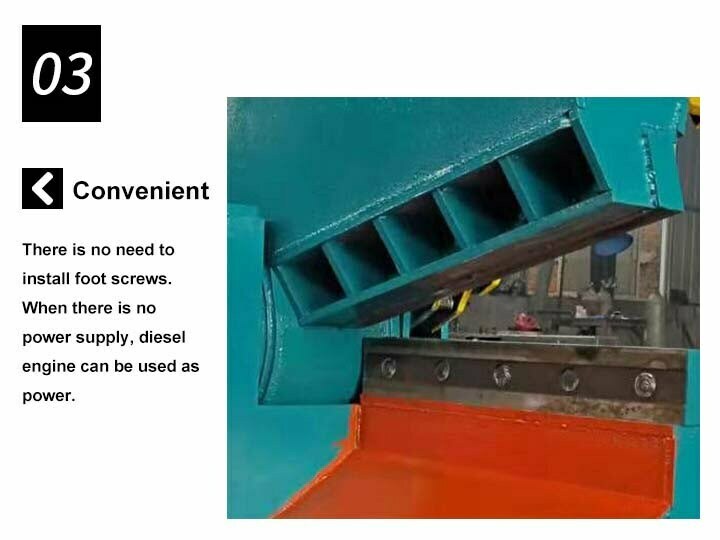

The alligator shears are hydraulically driven, with the characteristics of a small footprint, convenient use, simple operation, adjustable cutting length, and low working noise. The metal scrap cutting shear machine is divided into an upper cutter and a lower cutter. In the process of use, the material is first placed in the cutout of the machine, and then the pressure plate is gradually lowered and the material is firmly fixed on the stage. There are clearance teeth on the pressure plate, which can prevent the material from shifting during the cutting process.