Scrap metal chips briquette press machine | metal crumbs briquette machine

Metal chips briquette machine is also called vertical metal scrap recycling machine, metal chip merging machine, metal pressing machine, or high-density metal chip briquetting machine. The working principle of this machine is to use hydraulic pressure to press the metal which can produce plastic deformation into a solid block with high density.

Metal chips briquette machines can press iron chips, copper chips, aluminum chips, mineral powder, etc. into cakes for storage, transportation, and recycling in the furnace. The loss is very low after pressing into a block and recycling in the furnace. The whole production process does not need to add temperature, additives, or other processes, direct cold pressing molding, and molding at the same time to ensure that the original material remains unchanged. More convenient for recycling, the metal chips briquette press machine is widely used in the metal recycling industry.

Metal chips briquette machine applications

The metal processing process will leave a lot of trimmings, and these metal scraps are not convenient for storage, after the collection of briquettes metal block density increases, the handling process is not easy to scatter, and the hydraulic process does not require additives, so again recycling will not have too many impurities metal chips briquette machine is mainly used for cold pressing of powdery, granular, small flake copper scraps, iron scraps, aluminum scraps, alloy powder, stainless steel scraps, iron ore powder, magnesium powder, copper powder, and other metal scraps into 3-5 kilogram cylindrical cake. It can also be used for the pressing of non-metallic materials such as coke and slag powder.

Metal press shape can be customized

The scrap metal chips briquetting press machine can not only press the metal into a cylindrical shape but also into a square, triangle, and polygon shape by hydraulic pressure, which is convenient for recycling. In fact, the scrap metal chips briquette machine can be processed into any shape, one only needs to customize the mold can be, and Shuliy company can customize the machine for customers.

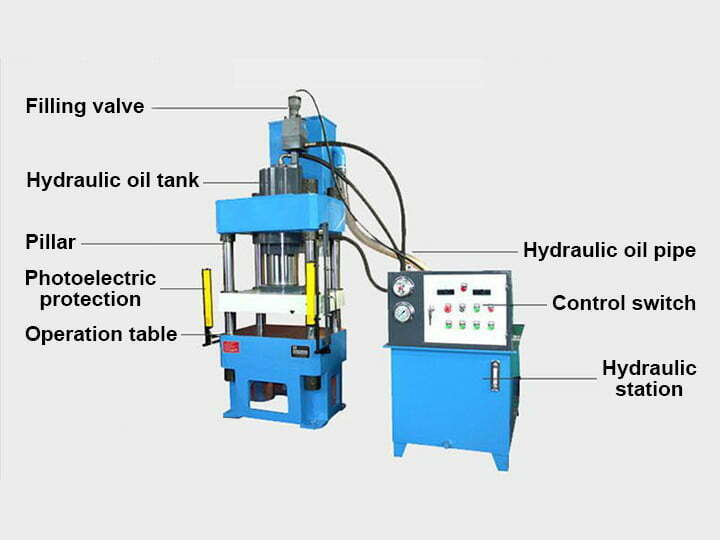

Introduction of metal chips briquette machine

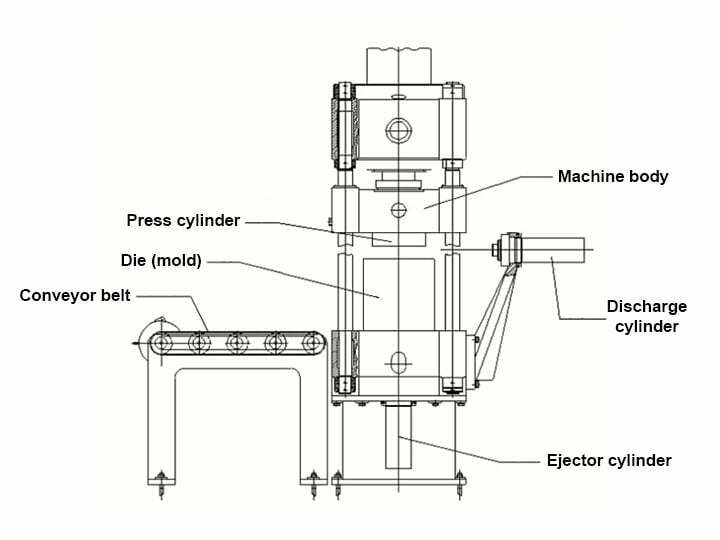

This machine is mainly composed of hydraulic rods, oil cylinders, four support columns, forming columns, molds, discharge plates, and other parts. The hydraulic system uses a two-way cartridge valve, which has the characteristics of small size, small flow resistance, good sealing performance, compact structure, stable operation, and long service life. The key to metal chips briquette machine is to have enough external force, and this hydraulic system can provide sufficient pressure. Compressing loose metal shavings into metal blocks with a density greater than 5.5 kg per cubic.

How does a metal crumb briquetting machine work?

First, put the loose material into the storage bin at the back of the machine. The material in the storage bin enters the forming mold of the machine. The hydraulic rod directly above the machine keeps dropping, and the loose material is compressed into compact high-density material blocks. The working efficiency of this machine is very high, it can produce 4-5 pieces in one minute. The machine adopts a PLC program for automatic control, which can realize fully automatic continuous production.

Hydraulic scrap metal chips briquetting press machine parameter

| Unit | Master cylinder | Acceleration cylinder | Push block cylinder | Dosing cylinder | |

| Nominal thrust | KN | 3500 | 237 | 229 | 80 |

| Cylinder inner diameter | mm | ∅400 | ∅125 | ∅135 | ∅80 |

| Piston diameter | mm | ∅220 | ∅70 | ∅70 | ∅45 |

| Itinerary | mm | 500 | 500 | 160 | 300 |

| Maximum pressure | Mpa | 25 | 25 | 16 | 16 |

The working efficiency of the metal chip briquetting machine is 4-5 pieces/min, and the machine is automatically controlled by the plc program. The metal briquetting machine has a cooling system, which can automatically control the temperature. In addition, we can customize it according to customer needs, welcome to consult.

Hydraulic scrap metal chips briquetting press machine features

1. Hydraulic metal chips briquette machine is mainly used for a variety of metal chips (iron chips, copper chips, aluminum chips, etc.), powder granular metal powder (iron powder, aluminum powder, copper powder, lead powder, etc.), smelting additives, sponge iron, etc. in the case of not adding any binder pressed into a high-density cylindrical cake block (weight 2-8 kg), cake block density up to 5T / M3 or more (different raw materials, pressed out of the cake block density is not the same weight ), the pressed briquettes can be used directly in the furnace.

2. Adopted hydraulic transmission technology, the use of oil seals, and oil cylinder processing assembly, so as to ensure continuous operation without weakening the cylinder pressure, smooth operation; computer control, high degree of automation, low failure rate, easy maintenance, etc.

3. Optional cooling system We recommend the right cooling system according to the working environment of the machine, air-cooled or water-cooled so that the machine does not strike.

4. High density of cake block High can press out the density of more than 5.5t/m3, and the cake block will not be broken when it falls.

Maintenance of metal crumbs forming machine

1. Regularly clean the oil tank and oil pipe of the machine to prevent iron filings and dust from entering the hydraulic system to affect the performance of the equipment.

2. Avoid overloading the machine. If there is an abnormal sound, stop working immediately.

3. Add hydraulic oil regularly, the liquid level must not be lower than the oil level of the oil tank.

4. Place the machine in a dry place and regularly check whether the screws on the machine are loose and whether the lubrication is good.