Cotton baling machine | cotton pressing machine

A cotton baling machine is used for cotton pressing. The machine bales the expanded cotton by compression, which is convenient for transportation and storage. Cotton baling machine is to use hydraulic compression to squeeze the gap between the cotton. Cotton balers can be used in cotton growing farms and quilt processing factories, etc. Our cotton pressing machine has been sold to Indonesia, Pakistan, Egypt, Sudan, Mexico, Saudi Arabia

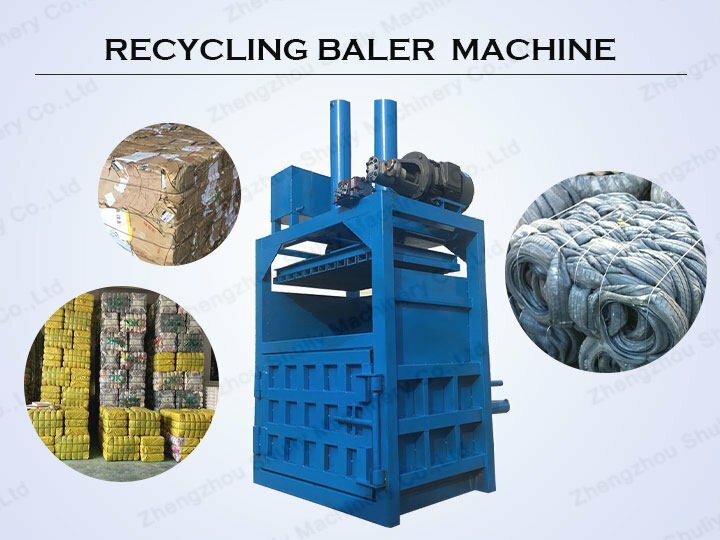

Application range of cotton baling machine

The cotton baling machine is mainly suitable for waste paper, plastic, iron filings, cotton, wool, waste paper, waste paper boxes, waste cardboard, yarn, tobacco leaves, plastic, cloth, woven bags, knitted wool, hemp, sacks, tops, wool Compression packaging of loose materials such as balls, cocoons, silk, hops, wheat firewood, grass, garbage, etc., reduces the volume, facilitates packaging, transportation and reduces storage space. It has a tight structure and is strong and firm.

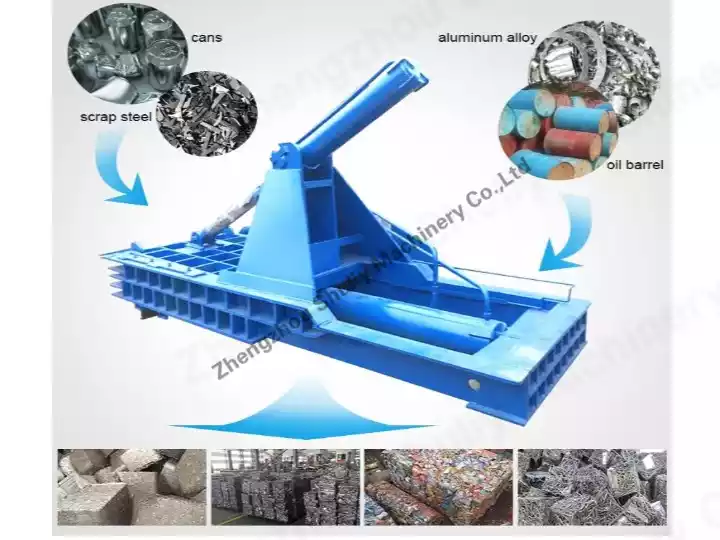

Two types of balers

In addition to this vertical baler, there is also a horizontal baler, which is more convenient for loading and larger in size. Vertical balers are generally used to pack lighter items such as waste, cotton, cans, and bottles. Type balers are used for baling raw materials with greater hardness such as scrap metal.

Cotton baling machine structure

The cotton baling machine includes a hydraulic cylinder, hydraulic valve, hydraulic mailbox, operating handle, thickened pressure plate, operating handle, pure copper motor, U-shaped door lock, and large-capacity compression bin.

Cotton baling machine advantage

High-pressure chrome cylinder

High-pressure chrome-plated oil cylinder, high-temperature resistance, long service life, no pressure relief, and no oil leakage

Thickened and upgraded pressure plate

The fuselage steel frame of the cotton baler is thickened for durability

High-quality motor

All copper core motor, fast heat dissipation, sufficient power, and long service life

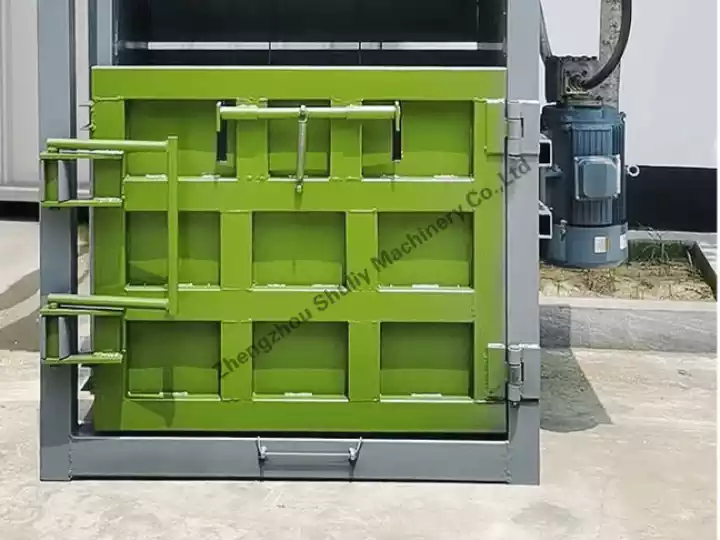

Security door

The cotton baler has a newly designed switch door, which is sturdy and durable.

Precautions for using cotton balers

(1) High-quality anti-wear hydraulic oil should be strictly used for the hydraulic oil added to the tank, which must be strictly filtered, and a sufficient amount of oil should always be maintained.

(2) The oil tank should be cleaned and replaced with new oil every six months, but the oil should not be cleaned and filtered for more than one month. The new oil that has been used once is allowed to be used again after strict filtration.

(3) Each lubricating part of the machine should be filled with lubricating oil at least once per shift as required.

(4) The debris in the material box should be cleaned up in time.

(5) Those who do not understand the structure, performance, and operating procedures of the machine are not allowed to start the machine without authorization.

(6) When the machine has serious oil leakage or abnormal phenomena during work, it should stop running immediately to analyze the cause and eliminate the fault, and must not be forced to run while sick.

(7) During the operation of the machine, it is not allowed to repair or touch the moving parts, and it is strictly forbidden to press the material in the material box with hands or feet.

(8) When adjusting the pump, valve, and pressure gauge, it must be done by experienced technical workers. If the pressure gauge is found to be faulty, the gauge should be checked or updated immediately.