Scrap metal baler | aluminum metal baling machine

| Model | Y81-1600A |

| Push Power | 1600 |

| Compressed warehouse(mm) | 1600*1000*800 |

| Baler size (mm) | 400*400 |

| Block density(kg/h) | ≥2000 |

| Efficiency(kg/h) | 2000-3500 |

| Single-cycle time(s) | ≤120 |

You can now ask our project managers for technical details

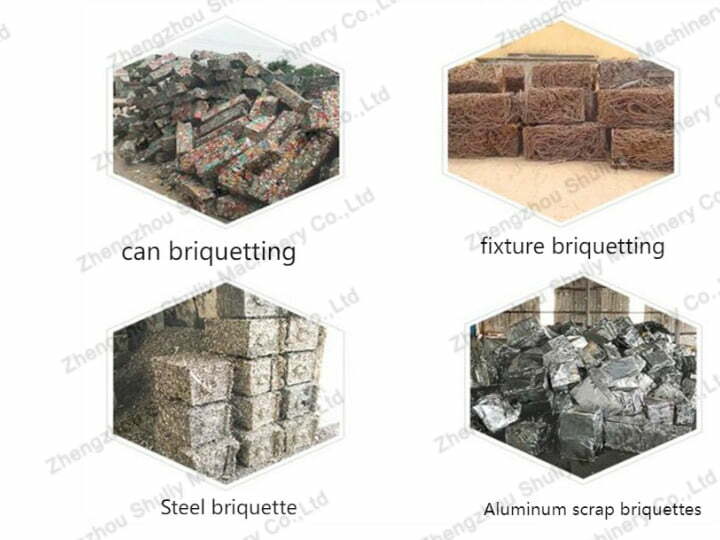

Scrap metal baler is used for metal recycling industry metal compression machine, through the processing of the machine can be irregular metal compression into a specific size of the square, easy to transport and storage, the metal baling machine can be used for the metal recycling industry, can also be used for scrap car recycling industry, waste paper baling, etc. The machine is simple and convenient to operate.

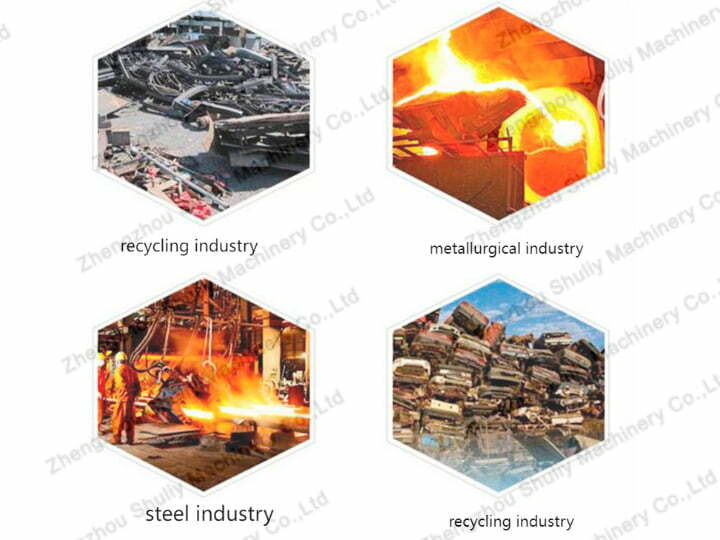

Application range of metal baling machine

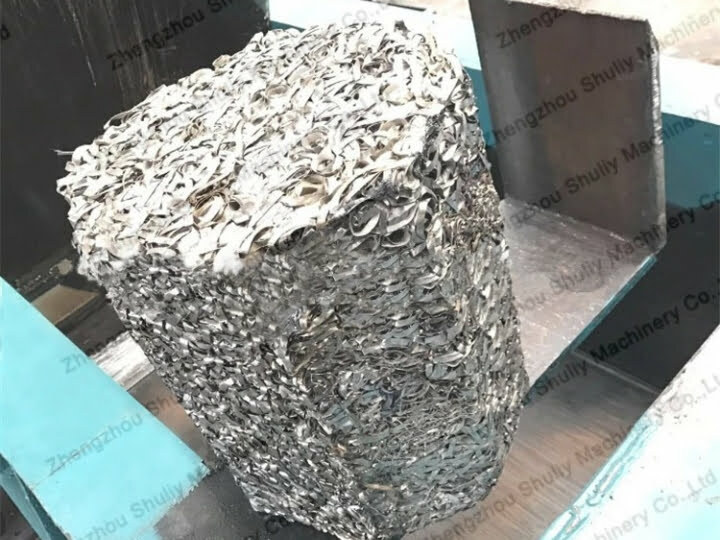

Scrap metal baler can extrude metal edges, steel shavings, aluminum, copper, and other metals into various shapes such as rectangular, cylindrical, hexagonal, octagonal, etc., as qualified furnace materials and reduce the cost of transportation. It can also be carried out to pack cans, plastic bottles, waste paper, and other products. Scrap metal baler is widely used in the metal recycling industry, metallurgical industry, steel making industry, and scrap recycling industry.

Why need to use a scrap metal baler?

Some scrap metal is disassembled from various products with different shapes, which brings inconvenience to storage and transportation. After being compressed and baled, the metal can be unified in size and can be listed, saving storage space in the warehouse. When transporting, you can use the crane and lift it directly, which saves the work efficiency when transporting. It also reduces transportation costs.

Why is the prospect of scrap metal good?

Metal mineral resources are non-renewable and will only be used less and less. In order to ensure the full utilization of metal resources, many countries have introduced many preferential policies for the metal recycling industry. Moreover, the state strictly prohibits the export of large quantities of metals without permission. Therefore, the metal recycling industry has begun to develop continuously. Scrap metal recycling is not only highly profitable but also conducive to saving resources and protecting the environment.

The operation of the scrap metal baler

Put the scrap aluminum or other metals that need to be baled into the trough, push the lever, and then you can carry out the baling, wait until the machine’s compression baling will be baled after the ejection of the metal block. There are four ways of discharging the machine: pushing forward, turning sideways, pushing sideways, or choosing the machine without automatic bale discharge.

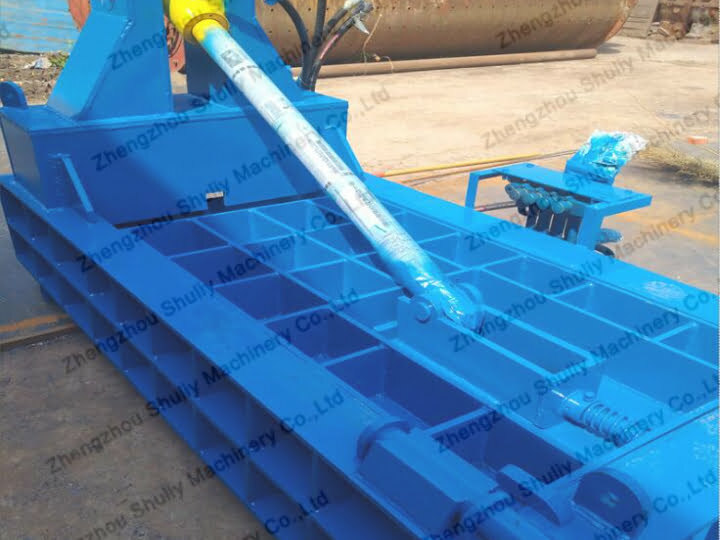

Scrap metal baler structure

Metal baling machine is composed of a body, main cylinder, side cylinder, cover cylinder, lock cylinder, high-pressure oil pump, hydraulic valve group, electrical system, and pipeline system. Metal baling machineadopts a hydraulic transmission system, compact structure, and simple operation.

Characteristics of scrap metal baler

1. Use the hydraulic transmission system. The machine runs smoothly and has low noise during work to ensure a good production environment.

2. Wide application. It can be used to process multiple materials and compress multiple materials into metal blocks of different shapes.

3. Wide selection. The pressure range of the machine is between 80-400 tons, there is always a machine to match your production needs. Of course, we also provide machines with pressure over 400 tons, if you need, you can customize them.

4. Save space. Compressing a large piece of metal into a denser piece of metal can save space and, in a sense, also save costs.

5. Easy installation. After the machine is assembled, it only needs to be placed on a flat floor, and no other installation is required.

Scrap metal baler parameters

| Model | Push Power | Compressed warehouse(mm) | Baler size (mm) | Block density(kg/h) | Efficiency(kg/h) | Single-cycle time(s) | Power(kW) |

| Y81-1250A | 1250 | 1200*700*600 | 300*300 | ≥2000 | 1200-1800 | ≤120 | 15 |

| Y81-1250B | 1250 | 1400*800*700 | 300*300 | ≥2000 | 1600-2300 | ≤140 | 15 |

| Y81-1350 | 1350 | 1400*600*600 | 600*240 | ≥2000 | 1600-2500 | ≤100 | 18.5 |

| Y81-1600A | 1600 | 1600*1000*800 | 400*400 | ≥2000 | 2000-3500 | ≤120 | 22 |

| Y81-1600B | 1600 | 1600*1200*800 | 400*400 | ≥2000 | 2000-4000 | ≤130 | 30 |

| Y81-2000A | 2000 | 1600*1200*800 | 400*400 | ≥2000 | 2500-4500 | ≤130 | 22/15 |

| Y81-2000B | 2000 | 1800*1400*900 | 450*450 | ≥2000 | 3000-5000 | ≤130 | 30/37 |

| Y81-2500A | 2500 | 2000*1400*900 | 500*500 | ≥2000 | 4000-6300 | ≤130 | 44/60 |

| Y81-2500B | 2500 | 2000*1750*1000 | 500*500 | ≥2000 | 5000-6300 | ≤150 | 44 |

| Y81-2500C | 2500 | 2000*1750*1200 | 600*600 | ≥2000 | 5500-6500 | ≤150 | 60 |

| Y81-2500D | 2500 | 2500*2000*1200 | 600*600 | ≥2000 | 5500-6500 | ≤150 | 60 |

| Y81-3150A | 3150 | 2000*1750*1000 | 500*500 | ≥2000 | 4000-6500 | ≤150 | 60 |

| Y81-3150B | 3150 | 2000*1750*1200 | 600*600 | ≥2000 | 5000-7000 | ≤150 | 60 |

| Y81-3150C | 3150 | 2500*2000*1200 | 600*600 | ≥2000 | 6000-8000 | ≤150 | 90 |

| Y81-3150D | 3150 | 3000*2500*1200 | 600*600 | ≥2000 | 6000-8000 | ≤160 | 90 |

| Y81-4000A | 4000 | 2500*2000*1200 | 600*600 | ≥2000 | 5000-7500 | ≤160 | 90 |

| Y81-4000B | 4000 | 3000*2500*1200 | 600*600 | ≥2000 | 8500-13000 | ≤160 | 90 |

| Y81-4000C | 4000 | 3500*3000*1200 | 600*600 | ≥2000 | 9500-14000 | ≤160 | 90 |

The parameter model of the metal baler represents the thrust of the machine. The larger the model, the greater the thrust of the machine, which means that a larger amount of metal can be processed. And it can be seen that each type of machine can produce metal blocks of the same specification. When purchasing, you can buy metal baling machine according to the size of the metal you want to process and the size you want to compress.

What factors affect the quality of the scrap metal baler?

Which aspects should we judge the quality of the metal baler? The machine can be selected from the material, hydraulic system, maximum pressure, etc. The temperature will rise when the machine is working, The temperature rise of hydraulic oil is affected by many reasons. It is found that when the oil temperature of hydraulic machinery rises, users can find the following reasons. Such as the heat dissipation of metal baler is poor. With the development of industry.