Copper Cable Granulator | Copper Wire Recycling Solution

| Model | SL-400, 600, 1000 |

| Uitset | 100–1000kg/h |

| Blades material | SKD-11 alloy |

| Copper purity | 99.5% |

| Application | copper wire scrap, aluminum wire scrap, etc. |

| Service provided | One-on-one solution planning, technical guidance, and production line configuration suggestions. |

Jy kan nou ons projekbestuurders vra vir tegniese besonderhede

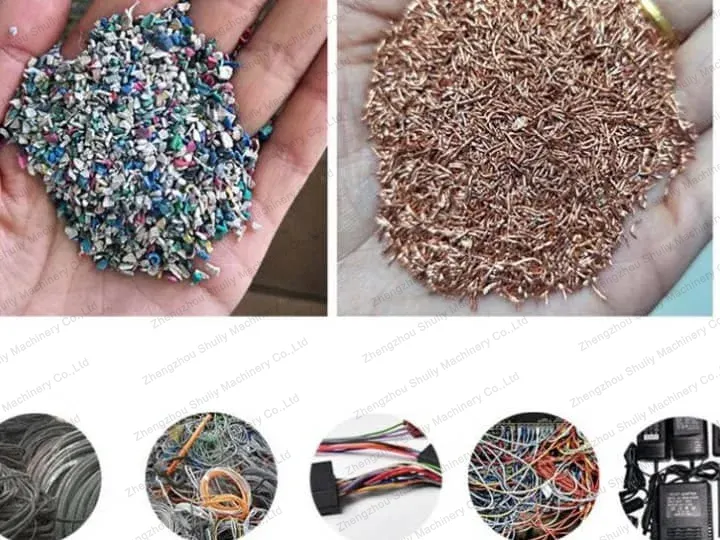

The copper cable granulator is used to process waste copper cables and copper wires. It efficiently separates pure copper particles from the plastic insulation layer through crushing, air separation, and gravity separation, transforming waste cables into high-value recyclable materials.

The final product has a copper purity of up to 99.5%, with an hourly output ranging from 100 to 1000 kg. Shuliy recommends using a production line for high-volume processing, or equipping it with electrostatic selection equipment to further separate any residual copper from the plastic.

Why choose Shuliy copper cable granulator?

- The copper recycling granulator recovers copper with a purity exceeding 99.5%, and can be equipped with an electrostatic separation device to achieve 100% copper recovery.

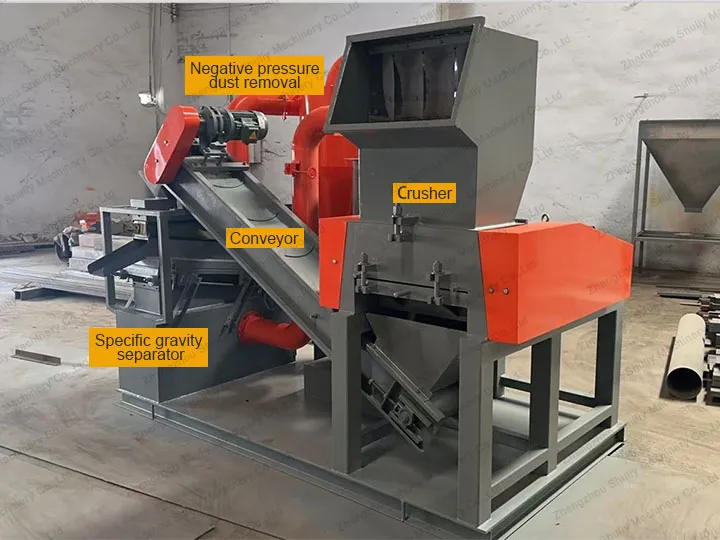

- Shuliy copper granulator adopts an integrated structure, occupying a small area, is easy to install, and is highly mobile.

- This machine is equipped with a PLC control system, allowing one operator to manage the entire production process.

- Our crushing device of this copper wire separating machineuses SKD-11 alloy blades (HR58 hardness) to ensure excellent wear resistance and toughness.

- The entire machine operates in a fully enclosed manner, with a pulse-jet dust removal device to effectively prevent secondary pollution.

Working principle of industrial copper wire granulator machine

Step 1: Waste copper cables and wires are fed into the crusher, where SKD-11 alloy blades break the material into uniform particles.

Step 2: An airflow and pneumatic sorting system separates the lighter plastic particles from the heavier copper particles.

Step 3: Air flotation gravity separation technology precisely separates copper and plastic based on density differences.

Step 4: A fully enclosed system combined with a pulse dust collector effectively removes dust generated during operation.

Step 5: Copper and plastic particles are collected and discharged from two different outlets.

Applications of copper cable granulators

Copper cable granulators are widely used in the recycling and metal regeneration industry, including:

- Recycling of waste copper wire and cable

- Recycling of aluminum wire and mixed metal cables

- Crushing and sorting of various waste wires

- Separating copper, aluminum, and iron from copper-aluminum radiators

The produced pure copper granules and plastic granules can be reprocessed separately or sold directly.

Technical parameters of the copper cable granulator

| Model | Afmeting | Kraakmasjien | Air conveying | Wind sorting | Dust collection | Uitset | Gewig |

| SL-400 | 2000×1850×2600mm | 15kw | N/A | 0.75 + 22kw | 0.75kw | 100–150kg/h | 1800kg |

| SL-600 | 4200×1900×3800mm | 37kw | 3 | 3.75kw | 2.2kw | 300–400kg/h | 3500kg |

| SL-1000 | 5180×2100×4200mm | 45kw | 4 | 3.75kw | 3kw | 800–1000kg/h | 4600kg |

Choosing a model based on actual production volume is a good approach, but many details require professional advice. If you have any questions about the machine, feel free to contact us for personal advice.

If you require equipment with higher output or greater automation, we also offer machine production line design and manufacturing solutions.

Copper wire granulation production line configuration

Depending on different capacity requirements and site conditions, copper wire granulators can be configured as small-capacity integrated solutions or large-capacity industrial recycling production lines.

400kg/h integrated copper wire granulator

Production process:

Crushing + Gravity separator + Negative pressure dust collector (Integrated Design)

Features:

- Integrated crushing and separation

- Extremely small footprint

- Easy installation, quick start-up

- Suitable for workshops, small recycling centers, and startups

We also have another type of production line with a capacity of 400 kg/hour, which is not integrated and is suitable for recyclers with higher precision requirements.

600kg/h copper wire granulation production line

Production process:

Granulating → Pipeline feeding → Gravity separator → Cyclone dust collector → Pulse jet dust collector

Advantages:

- Compared with single-integrated devices, it offers superior separation performance.

- Modular structure, easy to upgrade.

- Pipeline conveying for better dust collection.

1000kg/h copper cable granulation production line

This configuration is suitable for large-scale recycling plants and industrial-scale copper cable recycling projects.

Production process:

Conveyor belt feeding → Crusher → Conveyor belt conveying → Copper cable granulator → Electrostatic separation → Pulse dust collector

Process flow:

- Large pieces of waste copper cable are first crushed into smaller pieces.

- These pieces are conveyed to the copper cable granulator via a conveyor belt, where they become copper and plastic granules.

- The crushed material is then transported through pipelines to a gravity separation system.

- Copper granules and plastic granules are separated based on their density differences.

- A pulse dust collector captures fine dust, ensuring clean operation.

- The electrostatic separation unit further recovers residual copper powder from the plastic, maximizing copper purity.

Advantages:

- High output and stable performance

- Copper recovery purity is close to 100%

- Minimum copper loss from plastic

- Suitable for continuous, long-term operation

How to choose the right copper cable granulation production line?

- For limited space and low investment, choose an integrated copper cable granulator.

- For smaller production volumes but higher separation precision, choose a small-capacity production line.

- For large-volume recycling and higher product purity, use a large-capacity production line with electrostatic separation.

Shuliy can provide customized copper cable granulation solutions based on your raw material and production requirements, including production line layout, capacity planning, and equipment configuration. Contact us for the latest price list.

Related machines: