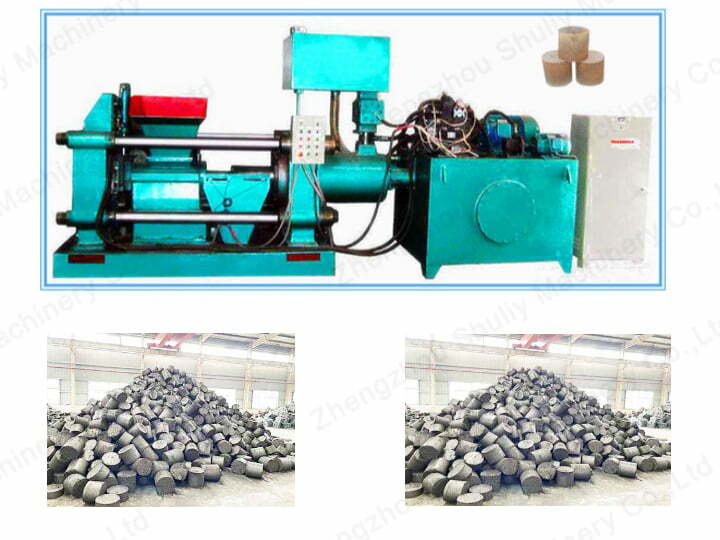

Metal shaving briquetting machine | aluminum chips briquetting machine

A metal shaving briquetting machine (horizontal metal chip compacting machine, metal chip/waste steel briquetting recycling machine) is the ideal equipment for processing copper chips, iron chips, and aluminum chips. Compared with the vertical metal briquette machine, although this machine has a large footprint, it has a larger pressure, which can press the metal chips into a high-density block under the action of a hydraulic punch. A must-have machine for the metalworking industry.

Brief introduction of metal shaving briquetting machine

The scrap iron briquette recycling machine is suitable for pressing various non-ferrous metals, such as stainless steel metal shavings, copper shavings, iron shavings, alloy shavings, zinc, bronze, and titanium, magnesium, etc. The metal chip briquetting machine is special forging equipment for the metal recycling industry. It can compact metal chips into high-density briquettes in a short time and then send them into the furnace to improve the utilization rate of the furnace. At the same time, it is also convenient for the storage and transportation of metal scraps.

Working principle of aluminum chips briquetting machine

Put the filings, lathe processing filings, shavings, iron filings, brass filings, aluminum chips, and other metal raw materials into the feeding hopper of the machine. The raw materials enter the forming mold of the machine through the hopper and are pressed by the hydraulic punch to make solid metal blocks. Then, it is pushed out by the pushrod and enters the discharge conveyor belt. This machine can be used with a bucket elevator, metal shredders, etc.

What are the dangers of recycling metal scrap directly?

- Iron filings are small in volume and high in density. Directly put into the furnace for smelting will block the rising channel of the furnace air and directly affect the melting effect.

- When the airflow in the furnace is large, the iron filings will be blown away, resulting in a low discharge rate.

- Iron filings can be easily attached to the furnace wall without briquette treatment, making the furnace wall thicker and more corrosive to the furnace.

- Scrap iron, silicon, manganese, and other materials are not easy to store. Their contact with water and air will cause oxidative deterioration. However, the melting point of iron oxide is higher than that of iron, which results in a long melting time and an increase in combustion cost

- Iron chips are easy to be wrapped by slag, resulting in the low utilization rate of raw materials.

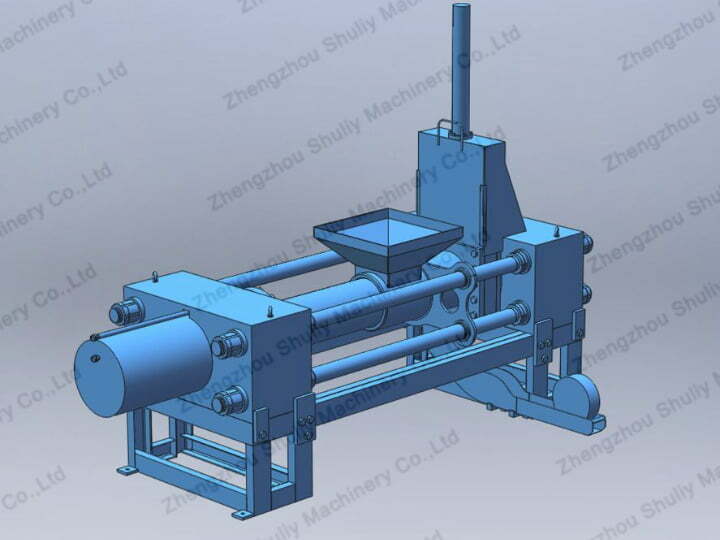

Aluminum chips briquetting machine structure

The price of a machine is often directly proportional to its quality. This machine is mainly composed of a base plate hydraulic cylinder, forming a hydraulic cylinder, pushing hydraulic cylinder, supporting mold frame and mold, press head, motor, hydraulic oil tank, over-pressure and over-current protection device, emergency stop protection device, control panel, etc. The electrical part adopts internationally famous brands to ensure that the machine can work continuously for a long time. The hydraulic system adopts advanced technology to ensure a tight connection and no oil leakage.

How much is a metal shaving briquetting machine?

Many machines don’t look very different from each other in appearance. Still, after comparison, it can be concluded that the price is related to the quality, and the price will be different for different models. The material used, the thickness of the machines’ material, the quality of the motor, and the manufacturing process are all factors that cause the different prices of the machine. Shuliy will design the most suitable production plan for customers and recommend suitable machines.

Metal shaving briquetting machine effect display