Metal Crusher Machine for Efficient Scrap Metal Recycling

Scrap Metal Shredder | Hammer Type Crusher

Model: BDL-600, 800, 1000, 1300, 1600, 1800, 2000

Speed: 860 r/min, 750 r/min, 650 r/min

Capacity: 600-18000 kg/h

Crushing range: Aluminum cans, scrap bicycles, broken aluminum window frames, and other scrap metals.

Output size: 3-10 cm

Hot-selling countries: India, Brazil, the United States, etc.

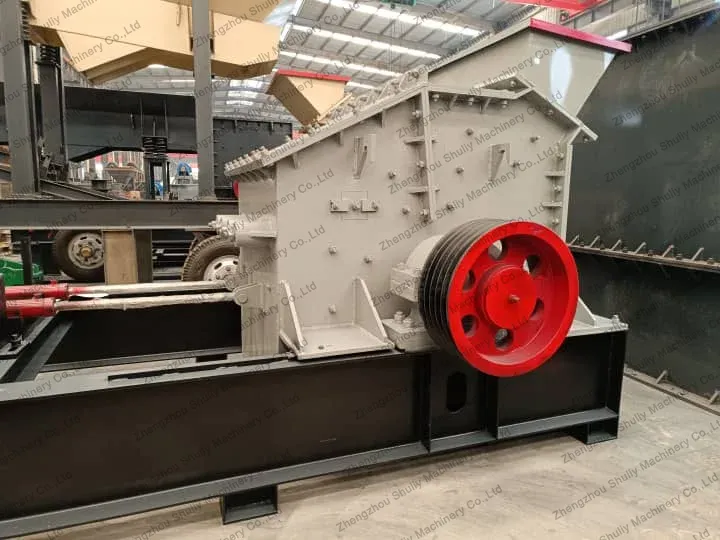

The metal crusher machine is an industrial recycling device used to shred, crush, and reduce the size of scrap metal materials such as aluminum cans and discarded vehicle parts, transforming them into uniform and easily manageable particles.

Depending on the application and the materials being processed, it can also be configured as part of a complete metal shredding production line, effectively helping businesses improve recycling efficiency and reduce transportation and storage costs.

How does a metal crusher work?

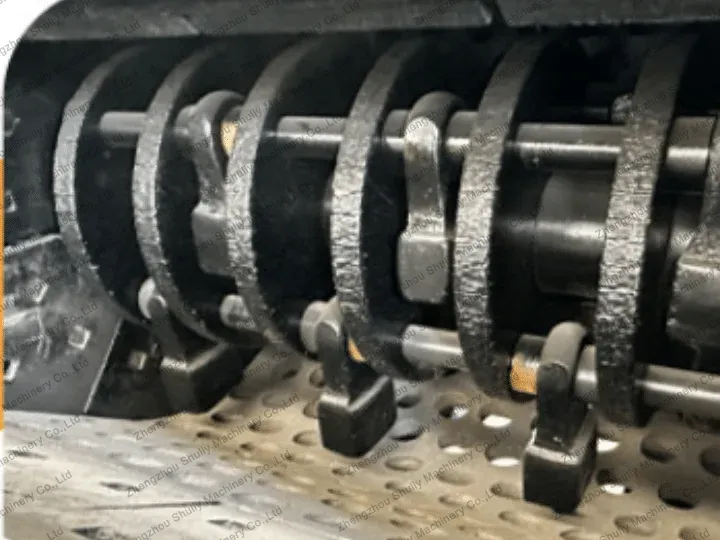

During operation, the metal shredder contains high-speed rotating hammers and blades that tear, crush, and deform various metal scraps into smaller pieces.

To control the finished product size, a screen plate is installed below the shredding chamber, allowing only metal fragments smaller than the screen size to pass through. The screen size can be adjusted according to processing requirements, typically ranging from 3-10 cm.

This equipment is suitable for fixed installation and centralized processing, and is usually integrated into a complete production line to effectively ensure stable operation and high output in large-scale metal recycling operations.

Key features of our metal crusher machine

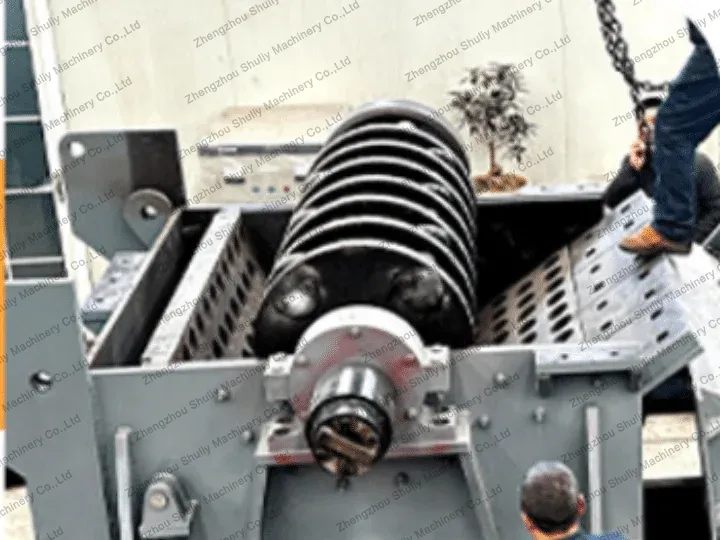

- This metal crusher features a heavy-duty rotor design made of reinforced cast steel, significantly enhancing radial strength. It is specifically designed for continuous operation under high loads, ensuring reliable performance even when crushing thick or high-density metal materials.

- It is equipped with hammerheads and screen plates made of alloy steel casting, offering excellent wear and impact resistance. The blade thickness and number can be customized according to different metal materials, flexibly adapting to various recycling needs.

- The metal crusher machine supports fully automated operation, so that the feeding and crushing processes can be fully automated with conveyor belts. It also makes the machine easy to integrate into a complete metal shredding production line.

- Shuliy metal can crusher is equipped with a full copper core motor, ensuring lower energy consumption, longer service life, and higher operating efficiency. This guarantees efficient crushing feasibility while reducing long-term operating costs.

- The body of the whole crusher is made of extra-thick steel plates, with high-tech welding and polishing techniques that ensure a robust and durable structure.

- Furthermore, the machine is equipped with motor overload protection and power interlock protection systems, effectively protecting the safety of operators and equipment.

Technical parameters of the metal crusher machine

| Model | Power | Speed | Capacity | Dimensions |

| BDL-600 | 18.5–22 kW | 860 r/min | 600–800 kg/h | 2000×1200×1900 mm |

| BDL-800 | 30–37 kW | 860 r/min | 800–1000 kg/h | 2200×1500×2200 mm |

| BDL-1000 | 55–75 kW | 860 r/min | 2500–3500 kg/h | 2800×1900×3100 mm |

| BDL-1300 | 90–110 kW | 750 r/min | 3500–5000 kg/h | 3500×2100×3800 mm |

| BDL-1600 | 110×2 kW | 750 r/min | 4000–8000 kg/h | 4400×2500×4200 mm |

| BDL-1800 | 160×2 kW | 650 r/min | 8000–12000 kg/h | 4700×2900×4500 mm |

| BDL-2000 | 220×2 kW | 650 r/min | 10000–18000 kg/h | 5000×3200×4600 mm |

Choosing the appropriate machine model requires considering factors such as material size, thickness, and required daily output. If the machine is to be integrated into a production line, the crushing rate and overall production line speed must also be taken into account for proper integration.

Shuliy has dedicated sales personnel who can provide recommendations based on your specific needs. If you have any additional customization requirements (Color, structure, etc.), please contact us to receive a free quote and customized service.

What types of recyclable materials can be processed by this crusher?

Shuliy metal crusher machines are suitable for processing various types of scrap metal, including:

- Flattened car bodies and dismantled car parts

- Lightweight materials with a density of ≤1 T/m³ after shearing or baling

- Old washing machines, refrigerators, air conditioners, color steel tiles, and other household appliances

- Scrapped motorcycles, electric vehicles, bicycles, and their body parts

- Waste aluminum cans, paint cans, scrap aluminum, and broken aluminum doors and windows (liquids and paint need to be removed)

- Scrap sheet metal, scrap steel, scrap iron, and other scrap metals

Contact us for the latest quota!

Most of our customers install the metal crusher machine or its related production line in their scrap metal recycling plants, steel mills, or smelters. By processing the materials, they reduce their volume, facilitating transportation or improving smelting efficiency, thus increasing the value of the recycled scrap metal.

If you are interested in our machine, please contact us for the latest price list and discounts. The following products can be used in conjunction with this metal crusher machine: