Shuliy 125T metal scrap baling press for Iron scrap disposal project in Malaysia

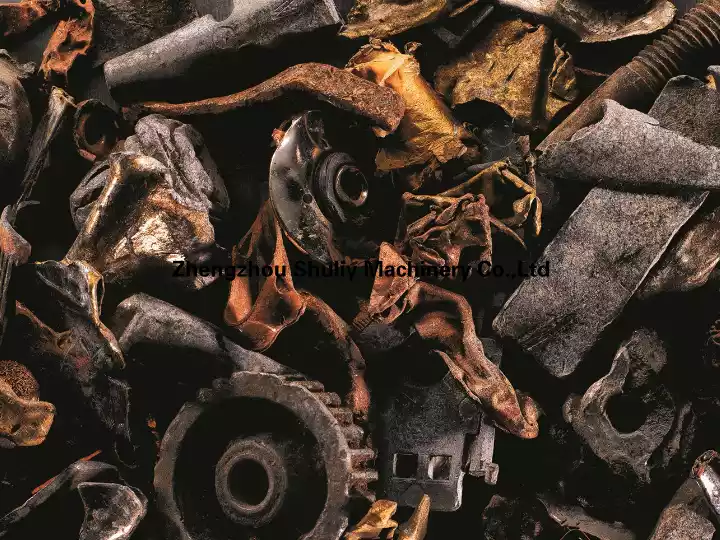

A metal recycling company in Malaysia was faced with the problem of disposing of large quantities of iron pins. In order to improve space utilization, reduce transport costs and enhance recycling efficiency, the company decided to introduce an efficient metal scrap baling press.

Metal scrap baling press selection and parameters

After detailed market research and comparison, the company chose Shuliy’s 125-tonne metal baler machine. The main parameters of the equipment are as follows:

- Model: 125 125Tons pressure

- Power:15kw

- Bale size:300*300mm

- Bin size:1200*800*500m

- Forming time:100s

- Pushing bale mode: side pushing bale, semi-automatic type

- Voltage: 380v, frequency 60hz, 3-phase electricity

Why choose Shuliy Machinery as metal baler supplier?

- Improvement of space utilization: The volume of the compressed iron scrap bales has been greatly reduced, resulting in a significant increase in the space utilization of the warehouse and transport vehicles.

- Reducing transport costs: Due to the increased density of the bales, the weight of iron scraps loaded per vehicle increases, thus reducing transport costs per unit weight.

- Enhance recycling efficiency: The metal scrap baling press is highly automated and easy to operate, which greatly shortens the time of iron pin processing and improves the overall recycling efficiency.

- Safe and reliable: Shuliy horizontal metal baler adopts high-quality materials and advanced manufacturing process, the equipment runs stably with low failure rate, which guarantees the safety of operators.