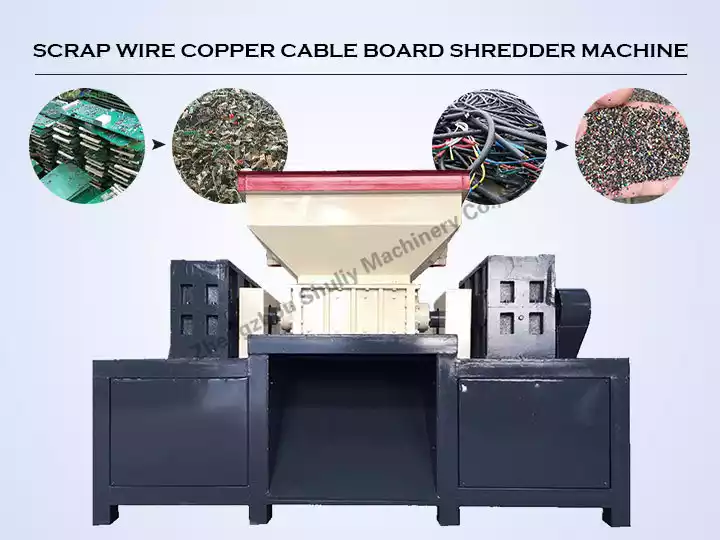

Scrap metal shredder machine | waste tire crushing machine

| Model | Sl-1000 |

| Power | 45KW*2 |

| Blade thickness | 50mm |

| Blade number | 20 |

| Dimension | 4500*1900*220mm |

| Weight | 1100KG |

You can now ask our project managers for technical details

The scrap metal shredder machine is used for metal shredders. It can be used for raw materials with metal scraps, as well as main automobile scraps, basic waste scraps, and other products. There are raw material scraps of metal shredders. Crushing of large metal raw materials for easy recycling and processing. It is used for the recycling industry, waste household appliance processing industry, and waste furniture metal crushing.

Scrap metal shredder machine raw material

The multi-function shredder is suitable for shredding all kinds of waste metal, wood, plastic, frame material, waste conveyor belt, iron cabinet, waste TV, refrigerator, air conditioner, washing machine, computers, mobile phones, freezers, etc., waste home appliances and home appliance shells, glass wool, glass, waste office supplies, motor shells, waste electrical appliances, battery shells, steel furniture, etc. The output size of the scrap metal shredder machine can be adjusted according to user requirements. The scrap metal shredder equipment adopts automatic control, and has the functions of starting, stopping, reversing, and overloading automatic reversing control, so that the user can reduce the damage to the equipment due to operation errors. According to the customer’s finished product requirements, different tool configurations are replaced, and the shredder shaft adopts the heat treatment process, so that the wearing parts of the whole machine are wear-resistant and durable, and the use is greatly improved.

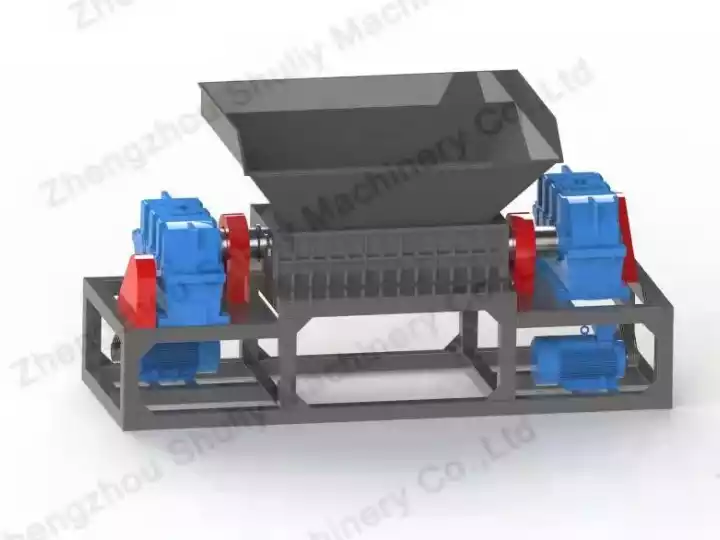

Scrap metal shredder machine structure

The structure of the metal shredder mainly includes the feed port, the discharge port, the cutter, the motor, the machine base, the reducer, etc. The machine rotates relative to each other through the two cutters, then squeezes the scrap metal, and then uses the cutter to cut the metal, usually large. After the piece of metal is put into the scrap metal shredder machine, the machine will decompose it by itself.

The feeding and discharging method of the waste tire crushing machine

Generally, the products that need to be put into this metal crusher are huge, such as scrap cars, iron barrels, old home appliances, etc. If the products to be broken are too large, tools such as tower cranes are required to put these things into the machine. Of course, if crush a very small product like a bike and throw it right into the machine. After the metal is broken, it will come out from the bottom of the machine. Conveyor belts can be placed under the machine for fully automatic flower production.

Waste tire crushing machine knife

The shredder knives are configured according to the model of the machine. Generally, the knives of large-scale machines are thicker. Generally speaking, the price will be higher. In addition, it is also related to the finished product. The knives are also related to the tooth density of the machine. There are different materials. If you want to crush tires, you can use 55SiCr cutters. If you want to crush light and thin metals, you need 9CrSi cutters, but if you want to crush metals that are thicker and harder, you need The highest strength knife, H13 material. That is to say, the tool of H13 material is used for materials of any strength. But 55SiCr tools cannot be used to cut thick metals. Pay attention when buying a metal shredder.

| material | Main application materials |

| 55SiCr(Five or five silicon iron) | wood, plastic |

| 9CrSi(9 soldered silicon) | rubber, metal |

| H13 | metal |

The advantages of the metal shredder machine

- Outlet size can be customized

- Wear-resistant and durable, the machine has a long service life

- Low noise and high efficiency when the scrap metal shredder machine works

- The scrap metal shredder machine has a strong seal and protects the operator

Metal shredder machine parameters

| Model | SL-400 | SL-800 | Sl-1000 |

| Power | 7.5KW*2 | 18.5KW*2 | 45KW*2 |

| Blade thickness | 20mm | 20mm | 50mm |

| Blade number | 20 | 20 | 20 |

| Dimension | 2000*1100*1620mm | 3800x1500x1900mm | 4500*1900*220mm |

| Weight | 1.1T | 3.5T | 1100KG |

There are many models of machines, the smallest model is SL-400, and the largest model is the SL-2000. We will recommend suitable models according to the products that need to be broken. we also have a scrap steel shearing machine for sale and another paper baler machine.