How Much Does A Tire Baler Machine Cost?

Shuliy tire baler machine is crucial equipment for the recycling and transportation of waste tires. It compresses bulk passenger-car, truck, and construction-machinery tires into high-density bales, reducing storage space by up to 75% and significantly lowering logistics costs.

What affects the price of a tire baler machine?

- The most crucial component of a tire baler is its hydraulic system. Its tonnage significantly determines the machine’s cost; higher pressure and stronger compression force result in higher costs. Common tonnages for tire baling machines are 60, 120, 200, and 250 tons.

- The bale size and the compression chamber determine the final size of each batch of compressed products. Larger compression chambers are more expensive but also more efficient, and can compress tens of tons of product at a time.

- In the machinery industry, higher levels of automation result in greater price differences, and of course, packaging efficiency also increases exponentially. The price range from highest to lowest is: Manual → Semi-automatic → Fully automatic.

- Well-known manufacturers typically charge higher prices, but offer better after-sales service, including spare parts support, remote operation support, and reliable machine warranties.

Is a tire baler worth the investment?

For most recycling companies, investing in tyre balers is one of the fastest-returning and most cost-effective upgrades to their waste tire processing lines, because balers can significantly transform the recycling process and profit structure.

Tire baler machines can reduce tire volume by 70% to 80%, allowing each truck to carry 3 to 4 times more material as bulk transport. This directly translates into savings in freight, labor, and warehousing costs, while reducing round-trip time and fuel expenses.

From a financial perspective, the return on investment is very attractive. Many medium and large-sized recycling companies reply that savings in transportation costs alone can recoup the equipment cost within 6 to 12 months. Companies with a large daily tire processing capacity may even reach break-even more quickly.

How to choose the right tire baler?

1. Determine the machine model based on the daily tire processing volume and scale, such as:

- <3t/h → Small baler

- 3t-10t/h → Medium baler

- >10t/h → Heavy-duty or fully automatic baler

2. Choose a machine with appropriate compression strength based on the type of tire you are dealing with, such as:

- Standard chambers are sufficient for passenger car tires.

- Medium-capacity hydraulic systems are recommended for light truck tires.

- Truck/construction machinery/agricultural tires require large-capacity chambers and high-tonnage hydraulic systems.

Choosing the right machine for your tire type can prevent overloading and extend its service life.

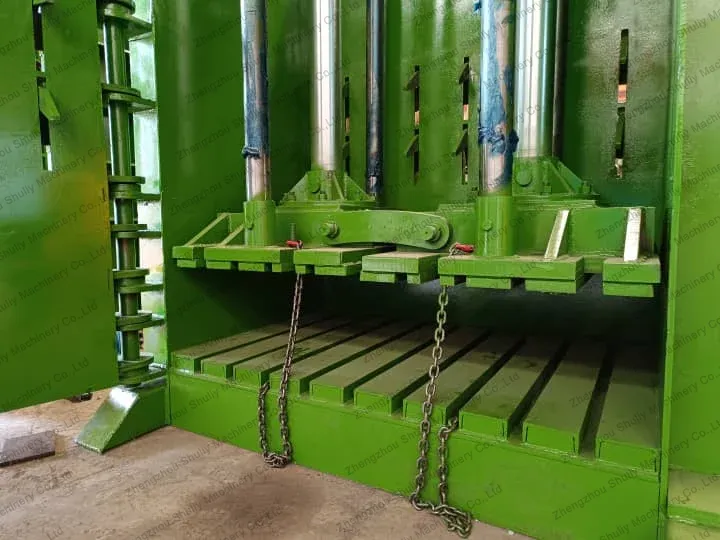

3. Shuliy’s tire baler machines are divided into vertical and horizontal types, and they differ slightly in their feeding methods.

- Vertical baling machines require manual feeding, which reduces efficiency.

- Horizontal baling machines can be equipped with a conveyor belt for fully automatic feeding, leading to higher efficiency.

The price of tire balers varies widely due to a variety of factors, but specifically depends on capacity, level of automation, and intended use. Waste tire recycling is growing globally, and investing in tire balers can significantly improve efficiency and reduce operating costs.

For the latest price list, please get in touch with me! We will provide you with the best prices for our tire baler machine and the most professional service.